Achieve Operational Excellence with Advanced Automation

Discover how automated quality control can significantly reduce shipping errors, enhance operational efficiency, and achieve long-term business success. Learn how ambitious leaders can leverage innovation to maximize productivity, ensuring sustainable growth and profitability for their enterprises.

Understanding Shipping Errors

Understanding the nature and impact of shipping errors is crucial for any business dealing in physical goods. Common types of shipping mistakes include mislabeling packages, sending incorrect quantities, and delivering to the wrong addresses. These issues can devastate customer satisfaction, spiraling into a vortex of complaints and negative reviews. Imagine eagerly waiting for a product only to receive something entirely different. It's a bad look.

Operational costs soar when shipping errors occur. Companies need to invest time and resources to rectify these errors, not to mention the added shipping costs to send replacement items. Plus, the internal chaos of handling returns and resending correct orders can throw even the most organized operations into disarray.

Brand reputation takes a serious hit due to shipping mistakes. Years of building credibility can crumble under the weight of negative feedback. In a world where competition is fierce and choices are endless, one bad experience can drive a customer into the arms of your competitors forever.

Traditional quality control measures often fall short in preventing these errors. Manual inspections can be inconsistent and prone to human error. Consider the exhausted warehouse worker trying to label hundreds of packages. It's easy to slip up, especially during peak seasons. Also, systems relying on outdated methods lead to inefficiencies.

The gap left by these traditional methods paves the way for the urgent need for automated solutions. Automation offers precision and efficiency that human processes rarely achieve. By employing technology, businesses can significantly reduce errors and enhance operational efficiency.

Automated quality control offers the promise of reducing shipping errors dramatically. Machine learning, AI, and robotics can augment human capabilities, ensuring accuracy and speed that traditional methods cannot match. It's about evolving with the times to consistently deliver on promises.

To further explore the intersection of automation and operational efficiency, visit our blog post about

retention sales using AI and automation. Embracing automation not only resolves shipping errors but aligns with overarching goals of growth and customer satisfaction.

The Role of Automation

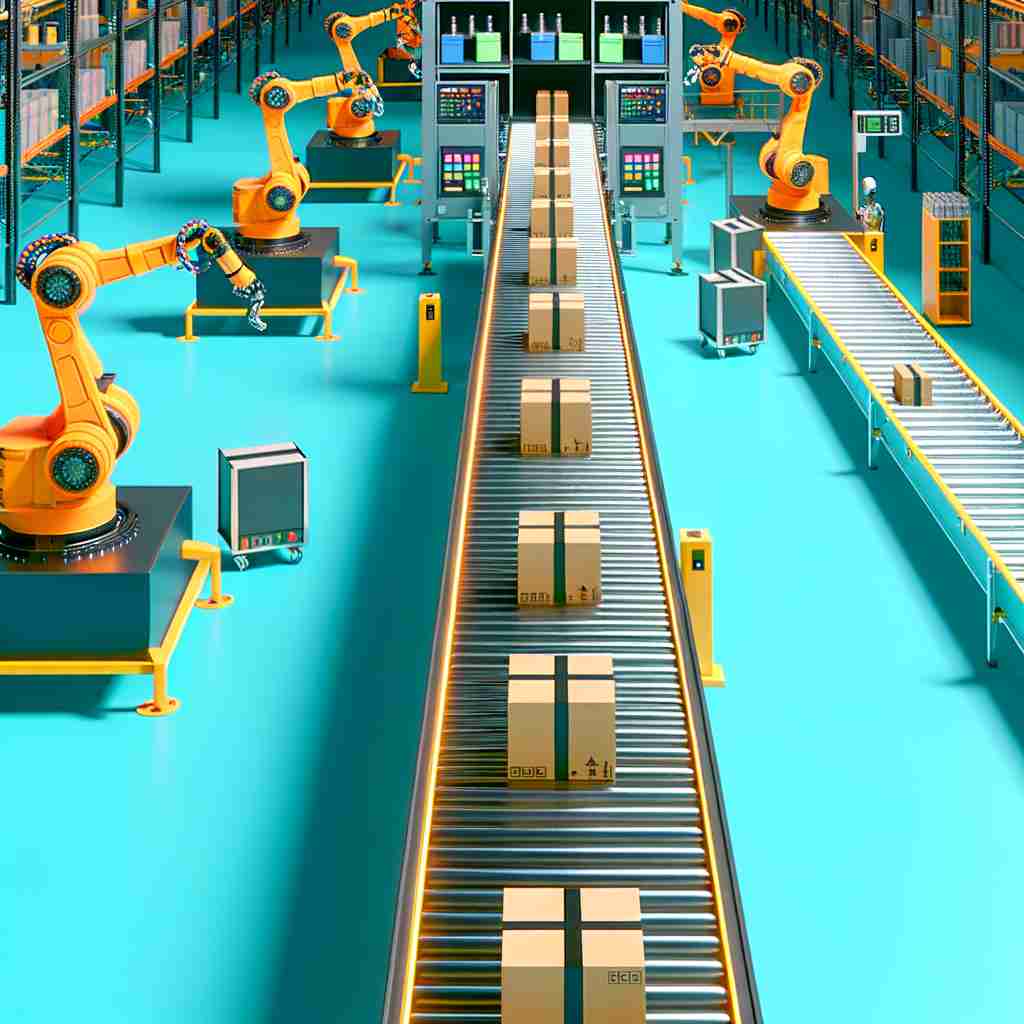

Automation in quality control is revolutionizing the way businesses approach shipping errors. By harnessing the power of machine learning, artificial intelligence, and robotics, companies can significantly reduce human error, enhance accuracy, and accelerate the shipping process. The role of automation is to meticulously analyze each step in the shipping process, ensuring precision in labeling, counting, and delivery locations.

Machine learning algorithms process vast amounts of data swiftly, learning from past errors to predict and prevent future mishaps. This continuous learning curve enables systems to adapt to changing patterns, which manual efforts typically struggle to keep up with. Robotics takes over repetitive tasks, ensuring that procedures like sorting, packing, and labeling are conducted with unfailing precision. This minimizes the fatigue and oversight issues that often plague manual operations.

Artificial intelligence plays a pivotal role by overseeing operations with an 'intelligent eye.' It identifies potential errors before they become costly mistakes, effectively operating as a vigilant gatekeeper that ensures quality in every package shipped. AI-driven systems can communicate insights across departments, fostering an environment of proactive problem-solving rather than reactive damage control.

Beyond error reduction, automation constrains operational costs by streamlining workflows and reducing the need for manual labor. Deploying automated quality control systems can yield dramatic improvements in shipping speed, satisfying customer demands for quicker deliveries. This not only enhances customer satisfaction but also bolsters brand reputation by consistently delivering on promises.

For Innersha Advisors LLC, the benefits of automation align perfectly with the company's commitment to scaling businesses effectively. By leveraging these advanced technologies, businesses are not only addressing shipping errors but also positioning themselves for sustainable growth. As detailed in our discussion on

retention and sales using AI and automation, this approach means more time for strategic development and less time fixing problems.

Integrating automation in quality control ensures that companies can maintain operational excellence while scaling. It frees human resources to focus on creative and strategic initiatives, laying a robust foundation for long-term success. This seamless alignment of technology with business goals enables enterprises to navigate the complexities of the shipping process with newfound confidence and reliability.

Implementing Automated Quality Control Systems

Recognizing the opportunity for improvement is the first step. Assess your current systems to identify gaps where shipping errors might creep in. This begins with a thorough evaluation of existing processes, understanding the pain points, and setting clear objectives.

Consider what you're aiming to achieve with automation. Are you looking to eliminate errors, save time, or both? With these goals in mind, you can tailor the solution to fit your unique business needs. At this stage, the expertise of Innersha Advisors LLC becomes invaluable. Their strategists guide businesses in pinpointing strengths and weaknesses, ensuring a targeted approach.

Once you've established your objectives, it's time to select the right technology. The choice depends on specific requirements—whether it’s machine learning for predictive analytics or AI-driven robotics for precise sorting. The crucial element is to choose technologies that integrate seamlessly into your existing framework.

Now, on to planning. This involves mapping out each step of the integration process. You want a system that not only fits but transforms and enhances your existing workflows. Create a roadmap that covers everything from setup to implementation, ensuring all stakeholders are aligned. Developing a well-thought-out strategy is crucial. This involves training the team, setting a timeline, and detailing the phases of execution.

Testing the system before full integration is essential. Run simulations and pilot programs to identify and correct potential hitches. This testing phase provides a buffer. It allows you to address issues before they impact your shipping operations on a larger scale.

Full integration follows successful testing. It’s where you can witness the fruits of your labor. A cohesive system should now operate with minimal human intervention, increasing accuracy and efficiency.

Finally, assess and adapt. Just like any innovation, continuous evaluation is necessary. Monitor the system’s performance regularly, seeking improvements and enhancing the process as your business evolves.

By leveraging

strategic planning and custom solutions, Innersha Advisors LLC ensures that businesses not only adopt new systems but thrive with them. Every business, regardless of size, can significantly reduce shipping errors and boost operational efficiency with a well-planned and expertly implemented automated quality control system.

Future of Automated Shipping

The future of automated shipping promises a thrilling evolution in how goods move around the globe. As businesses embrace this change, they set themselves up for a competitive edge. Innovations such as drone deliveries and advanced robotics are leading the charge. These technologies not only decrease human error but also increase efficiency. Imagine deliveries being faster and more reliable than ever before.

AI-powered predictive analytics are another game changer. With these tools, businesses can foresee potential shipping delays and optimize routes on the fly. This minimizes not just shipping errors but costs as well. Leaders who capitalize on these innovations can transform their shipping processes into seamless operations.

Blockchain, too, is shaking things up. It offers unprecedented transparency and security in the supply chain. This means less room for mistakes and greater trust among all parties involved. The technology is uniquely positioned to reduce fraud and increase accountability. Leaders who integrate blockchain into their logistics processes gain both efficiency and trust.

Autonomous vehicles are also set to make a substantial impact. From self-driving trucks to automated forklifts, logistics is entering a new era of automation. These vehicles promise not just accuracy but also safety and speed. They can redefine operations entirely, cutting down on human error and increasing precision in handling shipments.

Ambitious leaders have a choice: adapt or fall behind. Embracing these changes requires vision, strategy, and sometimes courage. It demands a willingness to leave outdated practices behind in favor of efficient, modern solutions. Those who are ready for this shift will need tailored solutions that match their unique requirements.

A proactive step involves seeking expert guidance in this transition. Services like Innersha Advisors LLC's pre-audit can provide essential insights. For businesses keen on harnessing automation, exploring tailored solutions becomes vital. These solutions help ensure that shipping operations are not just up-to-date but also ahead of the curve. Through targeted strategies, companies can seamlessly integrate innovations, reducing errors and boosting efficiency.

For more insights on transforming your business through automation, check out our blog on

retention sales using AI and automation. Don't wait to see how these trends can elevate your logistics game.

Final Words

Automated quality control significantly reduces shipping errors, leading to enhanced efficiency and increased profitability. By adopting these strategies, businesses can achieve sustainable growth and thrive in competitive markets. Embrace automation as a catalyst for innovation, ensuring consistent success and operational excellence.